-

微納3D打印系統

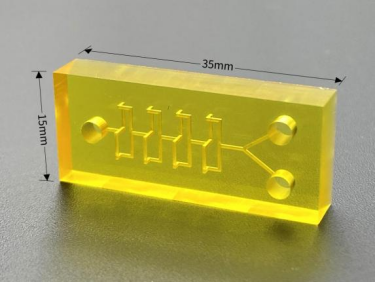

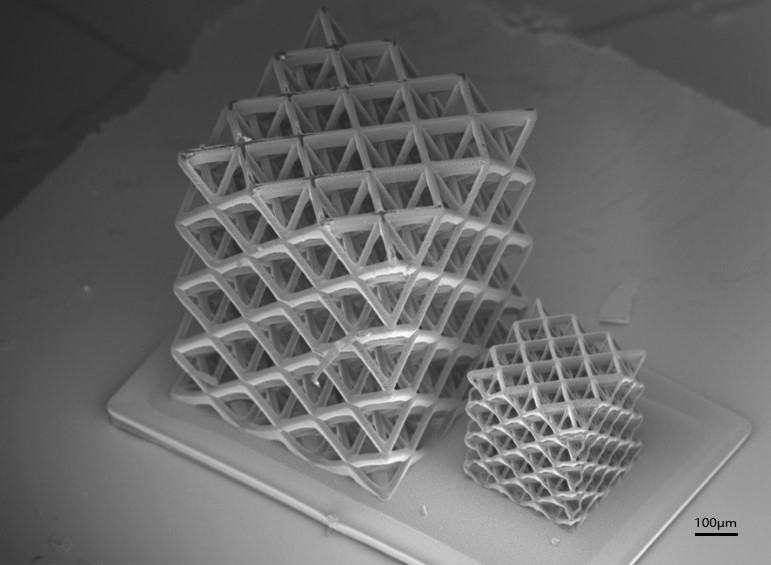

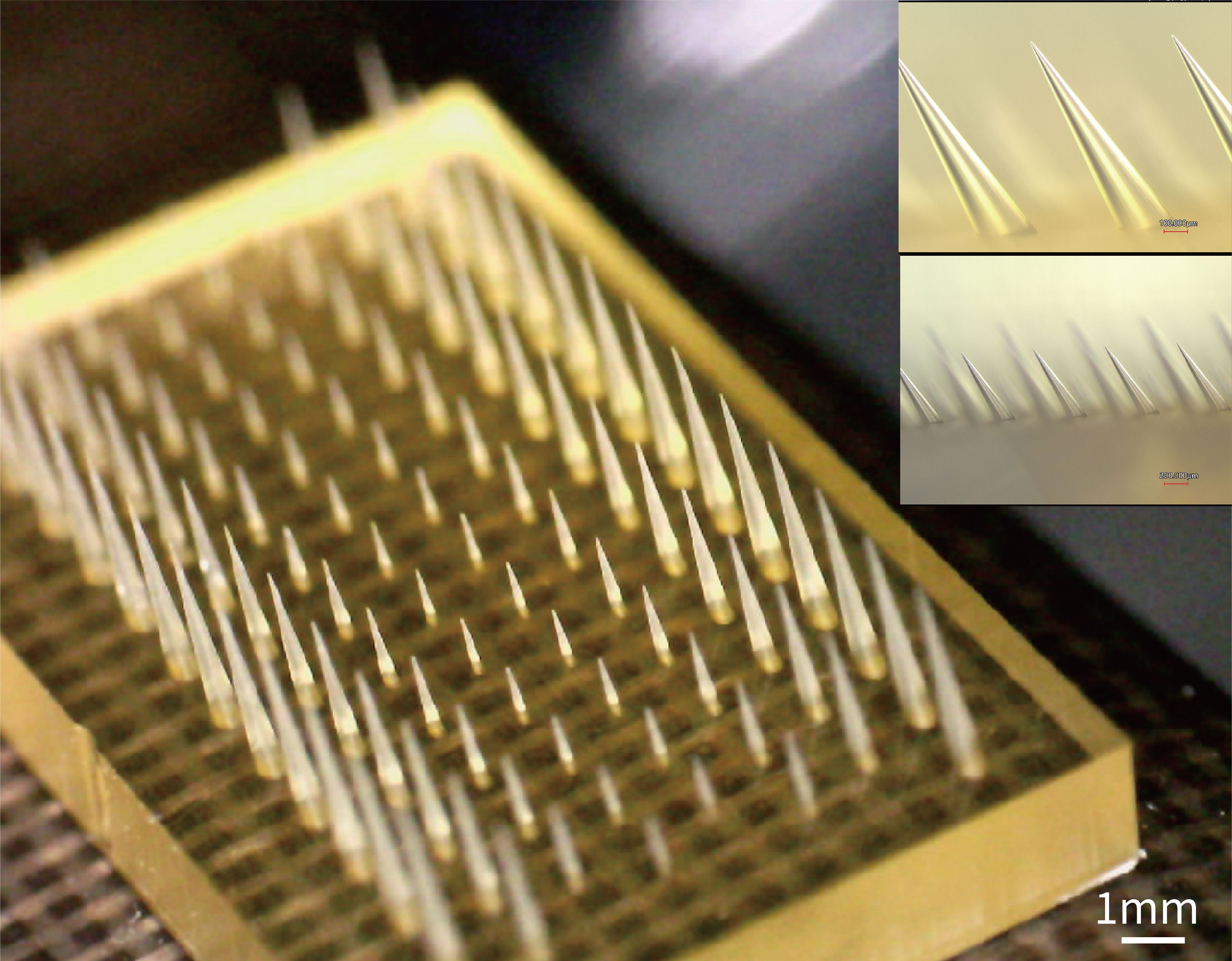

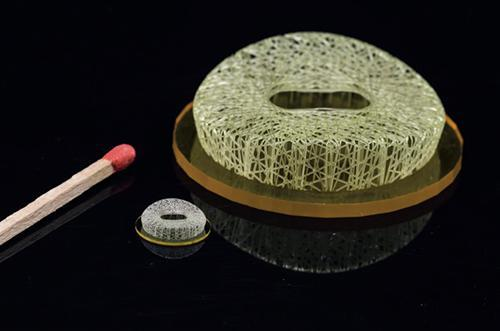

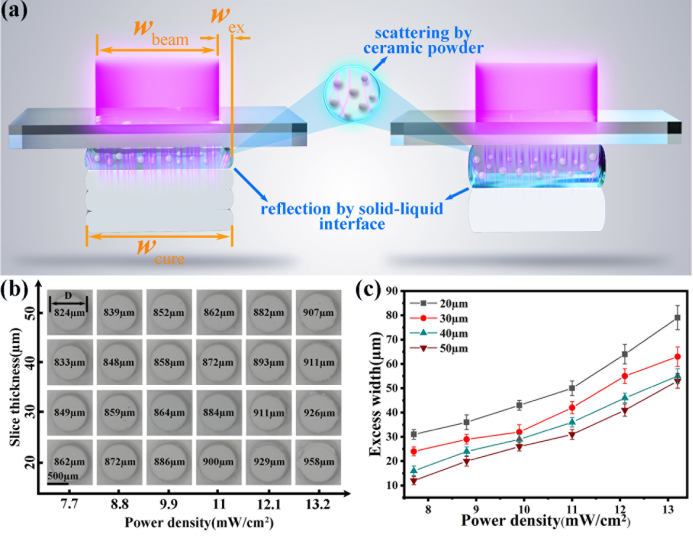

nanoArch?是第一款基于PμSL(面投影微立體光刻技術)技術的商業化超高精度,支持多種樹脂及陶瓷材料3D微加工設備,專為研究和開發功能復合材料而設計。

-

3D打印服務

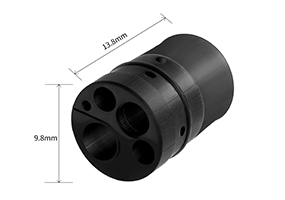

專注于精密器件免除模具一次成型能力的研發,提供制造復雜三維微納結構技術解決方案,同時,可結合不同材料及工藝,實現終端產品高效、低成本批量化生產及銷售。

-

應用案例

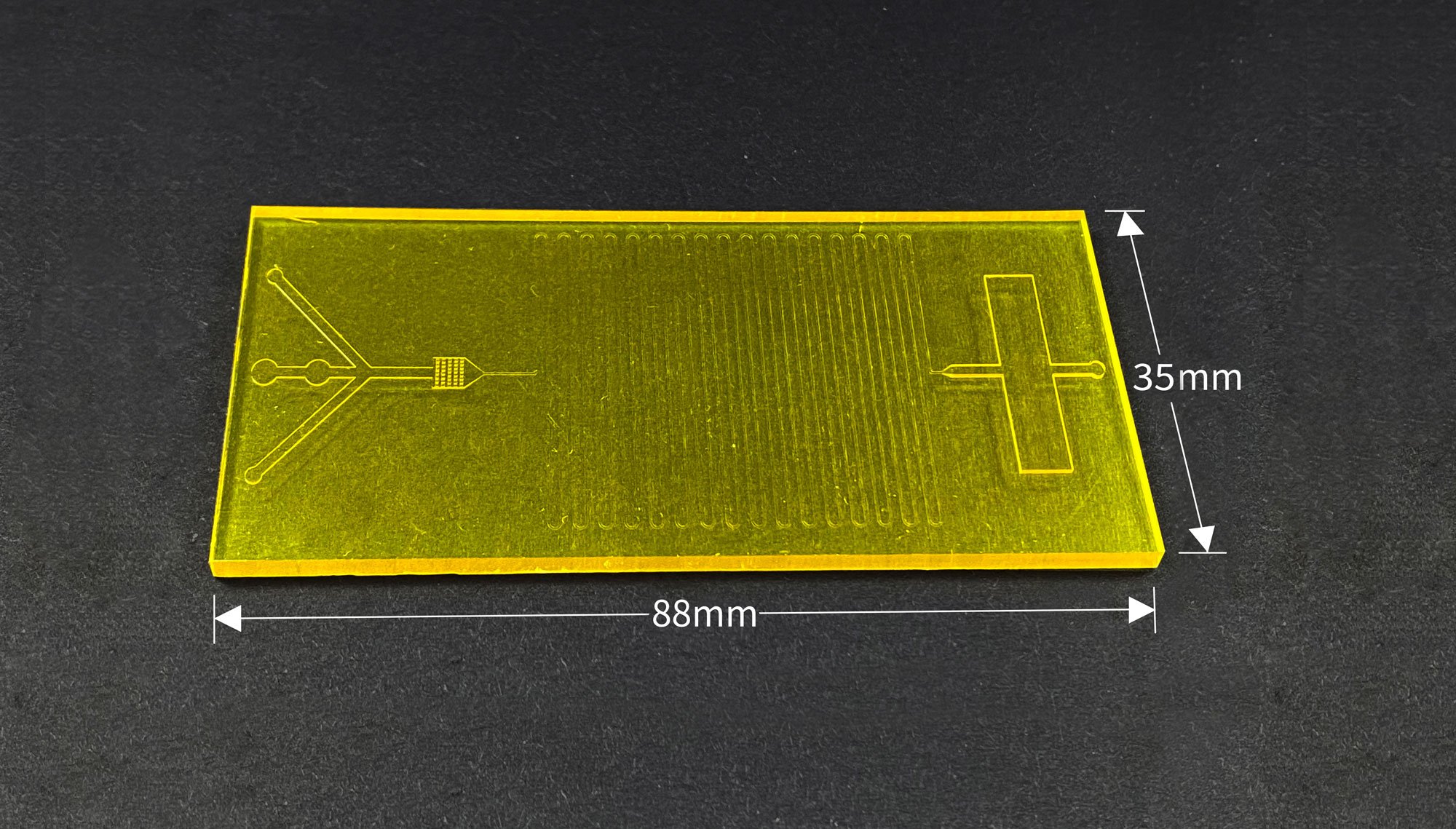

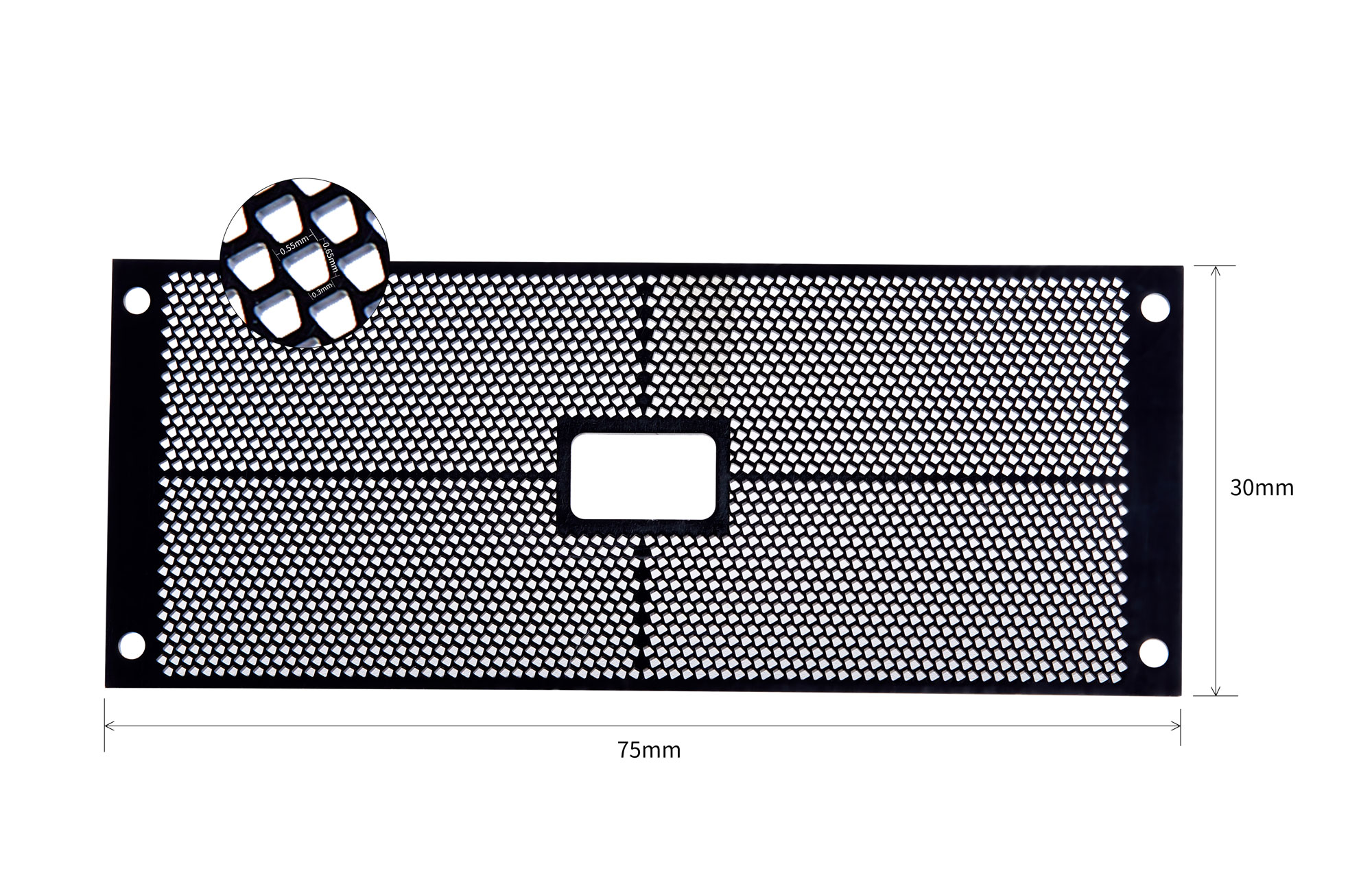

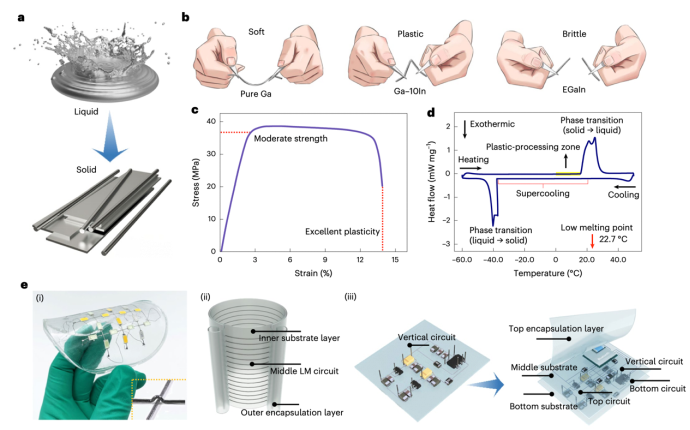

BMF高精度3D打印技術應用領域已涵蓋精密醫療器械、精密電子器件、微流控、微機械、科研領域等。

-

打印材料

摩方能夠提供多種高性能3D打印材料:405nm固化波段的通用型光敏樹脂,可支持硬性樹脂、韌性樹脂、耐高溫樹脂、生物兼容樹脂、耐候性樹脂、陶瓷漿料等,可根據打印樣品的要求選配不同材料。

客戶案例

新聞中心

+

- 新聞

- 媒體報道

客戶評價

摩方精密的3D打印件精度很高,對于我們連接器的設計可以完成結構性驗證的過程,而且打印速度很快,很好的解決了原先需要開模而導致周期長,投入大的問題。而且一但有修改,很顯然速度也很快,這種優勢是開模所無法比擬的。

安費諾公司,王翔,供應鏈經理

開立醫療公司,邵工

香港城市大學,陸洋,教授

清華大學工程力學系,李曉雁,長聘教授

南方科技大學,葛锜,副教授

大連理工大學,馮詩樂,副教授

上海交通大學,朱麟勇,教授

Sally van der Most, DSS Manager, Sonion NL

Donna Bibber, VP of Business Development, Isometric Micro Molding, Inc.

James Grimm, Senior Business Development Manager, Empire Group

獎項

棱鏡獎介紹

摩方精密S240 在 SPIE 2021 Prism Awards 中贏得制造類大獎

摩方精密S240 在 SPIE 2021 Prism Awards 中贏得制造類大獎

我們很榮幸microArch S240榮獲 2021 年 Prism 制造獎。

棱鏡獎是國際光學工程學會(SPIE)聯合Photonics Media于2008年創立,是目前全球光電行業的最高獎項。

棱鏡獎是國際光學工程學會(SPIE)聯合Photonics Media于2008年創立,是目前全球光電行業的最高獎項。

紅點獎介紹

摩方精密S140在2019年獲得紅點獎(外觀設計類)

摩方精密S140在2019年獲得紅點獎(外觀設計類)

是與IF設計獎齊名的一個工業設計大獎,是世界上知名設計競賽中最大最有影響的競賽。

Nano 3D Printing System